Biochar: The Carbon-Negative Powerhouse Driving India’s Net-Zero Future

Complementing India’s 2070 vision for net-zero emissions, biochar has emerged as a global

favourite when it comes to carbon negative biofuel systems. From renewable energy production

to industrial carbon sequestration, biochar finds many applications to offset carbon footprint,

Sunil Dhingra details.

Introduction

Rising industrialization and population growth have drastically increased energy demand and fossil fuel dependency, leading to alarming greenhouse gas emissions. The atmospheric CO₂ levels rose from 315 ppm in 1958 to around 417 ppm in 2023, intensifying global warming through enhanced heat absorption and re-radiation. At the same time, open burning of agricultural residues especially in Punjab, Haryana and Uttar Pradesh continues to pollute the air.

Biochar—a carbon-rich by-product of biomass pyrolysis—is gaining global traction as a powerful enabler of renewable energy and carbon negative biofuel systems. In India, with its vast agricultural residues and climate challenges, biochar offers a sustainable path to convert waste into clean energy and long-term carbon storage. According to Global Biochar Market Report 2025, the industry is set to grow from $3.1 billion in 2025 to $6.5 billion by 2030 at a 13.8% CAGR, with over 6,00,000 tonnes/year produced globally. Its rising demand spans energy generation, bio-oil production, carbon credit markets, and sustainable agriculture—positioning biochar at the heart of the circular, low-carbon economy.

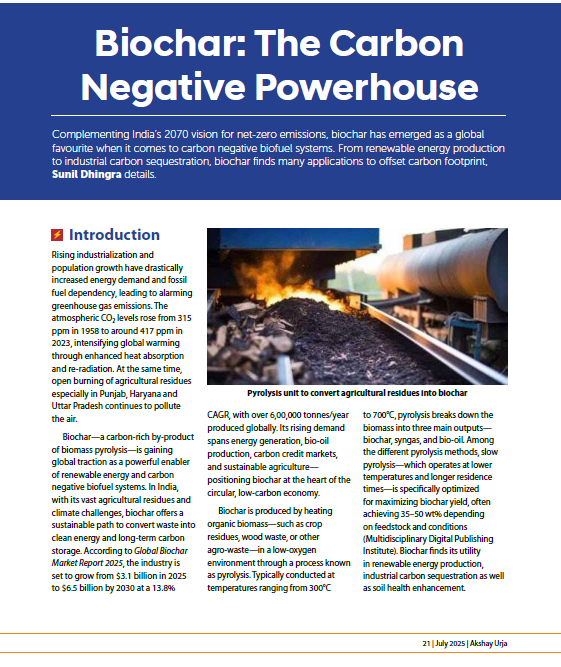

Biochar is produced by heating organic biomass—such as crop residues, wood waste, or other agro-waste—in a low-oxygen environment through a process known as pyrolysis. Typically conducted at temperatures ranging from 300°C to 700°C, pyrolysis breaks down the biomass into three main outputs—biochar, syngas, and bio-oil. Among the different pyrolysis methods, slow pyrolysis—which operates at lower temperatures and longer residence times—is specifically optimized for maximizing biochar yield, often achieving 35–50 wt% depending on feedstock and conditions (Multidisciplinary Digital Publishing Institute). Biochar finds its utility in renewable energy production, industrial carbon sequestration as well as soil health enhancement.

Biochar as a Fuel

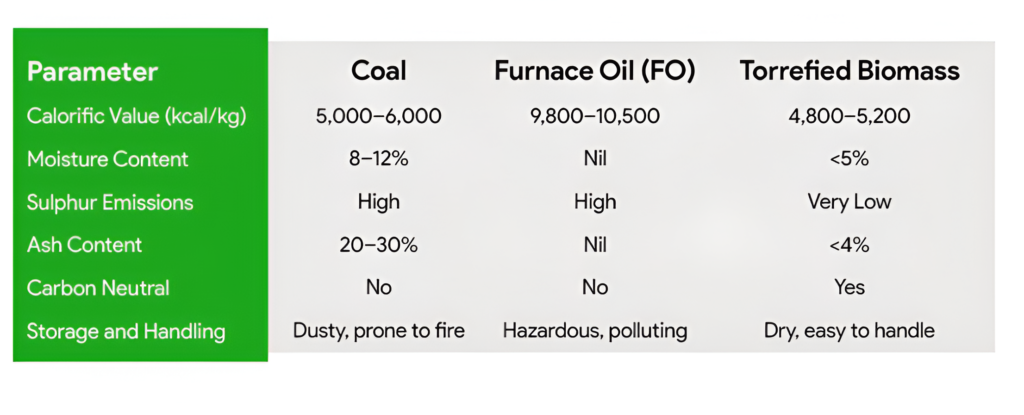

Beyond its carbon sequestration potential (1 tonne biochar = up to 3 tonnes CO₂e stored), biochar is a high-energy solid fuel, with a calorific value of 22–30 MJ/kg and fixed carbon content of 65–85%, comparable to sub-bituminous coal. Its low moisture (<5%) and volatile matter (10–25%) enable efficient combustion with fewer sulphur and nitrogen emissions. While combustion releases stored carbon, biochar can be used for energy in hard-to-abate sectors like cement or biomass power, especially when it is not suitable for soil use.

Co-firing biochar with coal in thermal power plants offers a practical emission-reduction strategy. A 10–20% blend can reduce CO₂ emissions by 8–27%, and even a 5% global coal substitution could save 300 million tonnes of CO₂ annually. Similarly, bio-oil, a pyrolysis by-product, when blended at 35–60%, can cut GHG emissions by 60–75% per kWh, offering further decarbonization potential.

Biochar: Feedstock Enhancer in Biofuels

Biochar significantly improves the efficiency of biofuel systems. In biogas plants, adding 5% biochar to mustard straw feedstock increased biogas yield by 40.5% and methane yield by 188.8% under mesophilic conditions (Chen et al., Bioresource Technology, 2020).

In biodiesel production, biochar works as an effective catalyst and filter. Yields of 92.4–95.2% have been reported using biochar derived from seed residues and wood under optimal conditions (Energy Conversion and Management, 2020). Overall, biochar boosts process efficiency and supports cleaner, high-yield biofuel production.

Carbon Credits from Biochar

In 2024, both the Intergovernmental Panel on Climate Change (IPCC) and the United Nations Framework Convention on Climate Change (UNFCCC) officially acknowledged biochar as a viable method for permanent carbon sequestration, making it eligible for carbon credits.

On voluntary carbon markets, biochar-based carbon credits are currently valued at $100–$180 per tonne of CO₂e, depending on project certification, feedstock type, and methodology used.

India, under the National Bio-Energy Mission and aligned with global standards like Verra’s VM0044 methodology, is exploring frameworks to scale up biochar credit generation, especially from decentralized agro-residue management projects. With the country generating over 728 million tonnes of agro-residue annually, India holds immense potential to become a major hub for biochar-based carbon finance while tackling residue burning.

Biochar and India’s Net Zero Goal

India has pledged to achieve net-zero emissions by 2070, and biochar can play a strategic role in accelerating this transition. Large-scale biochar deployment in industries can help sequester millions of tonnes of CO₂ annually, reducing methane emissions from decomposing organic waste, which is over 80 times more potent than CO₂ in the short term.

If India were to convert just 5% of its crop residue (~35 million tonnes/year) into biochar, it could prevent the release of 75–90 million tonnes of CO₂ equivalent annually. This industrial-scale production would not only contribute significantly to India’s net-zero targets but also support green manufacturing, reducing industrial emissions, and boosting sustainable agriculture.

Biochar in Sustainable and Climate-Resilient Agriculture

Biochar exhibits properties that make it highly effective in enhancing soil health and agricultural resilience. Its composition varies with feedstock and production conditions, but typically contains up to 77% stable carbon, with low moisture (~4.7%) and volatile matter ranging from 5–30%, allowing it to persist in soils for centuries.

With a porous structure, pH between 6.5–10, and Cation Exchange Capacity (CEC) reaching 150 Cmol/kg, biochar improves nutrient retention, soil aeration, and microbial diversity, especially in acidic or degraded soils.

It also features electrical conductivity (0.5–5 dS/m), impacting nutrient availability. Applied directly or blended with compost, biochar enhances moisture retention, plant health, and drought resistance. Moreover, by sequestering carbon and reducing fertilizer runoff, it serves as a key tool for climate-smart and regenerative agriculture, boosting both yield and resilience to climate extremes.

Challenges in Scaling Biochar

Scalability: Decentralized models face financial and logistical challenges.

Standardization: Need for standardized quality and carbon accounting protocols.

Awareness: Farmers and industries still lack technical awareness of biochar’s multiple benefits.

Conclusion

Biochar sits at the nexus of energy, environment, and agriculture—transforming agro-waste into renewable energy while sequestering carbon for centuries. As global carbon regulations tighten and ESG mandates grow stronger, biochar is poised to become a core enabler of energy sector, circular bioeconomy, and net-zero strategies. Its integration with biofuels, green financing, and climate-smart practices unlocks a scalable, carbon-negative solution for India and the world in the fight against climate change.